No Food Waste

Respect for food

Food wastage is an ever-present issue: a third of all food is simply thrown away. Our priority is to respect the delicious bounty Nature provides and to accept responsibility for contributing to a healthy environment. “No food waste” is something that affects all of us – consumers just as much as producers.

Because of this, being efficient with food is an important part of our sustainability strategy. For us, “No food waste” means not wasting any of the raw material during the cheese production process.

You can learn more here about how this can be achieved:

Milk from Swiss dairy farms

We need approx. 10kg of fresh, silage-free milk to produce 1kg of cheese. We only use milk from cows fed on fresh grass or hay, and reared in an appropriate manner.

Cheese production

100 percent of this milk flows into the production of our cheese. The cheesemaking process results in around 9kg of whey being produced per kilo of cheese. The whey contains approx. 4% of the lactose, precious whey proteins (globulin & albumin), and other vitamins and minerals. The whey is drained into a curd tank and centrifuged. This then produces approx. 1 thousandth whey cream, which we mix back in with the milk.

Once the whey cream has been removed we are left with lean curd. This is thickened and the resultant concentrate sold as animal feed. The byproduct from this process is water, some of which we use to flush the systems.

For low-fat cheeses, we remove the cream during the cheesemaking process. We use the cream that has been removed for other types of cheese. Alternatively, it may be sold as a separate product.

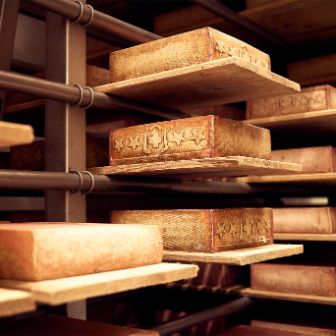

Maturation cellar

We use a greasing robot to assist us during the maturation process. Every now and then, the robot causes small deformations or optical defects in the cheese. We weed out these cheese rounds and use them to make grated cheese, fondue or processed cheese. Even old cheese rinds are not thrown away but supplied to a biogas facility as a raw material.

Packaging

Of course, we also think about sustainability when it comes to our packaging. We package our cheese rounds for delivery in eco-friendly waxed paper.